Inkling carrying out modelling to assess window film performance

Inkling have been doing some work with Eastman to explore the properties of some of their glazing films and how well the dynamic thermal modelling tools (TAS and IES) can pick up their benefits. It has been an interesting exercise and we thought we’d share some of what we’ve learned in this blog post.

Glazing is a remarkable building product and its exact specification can make a huge difference to the thermal performance and comfort of a building through the year. At Inkling we spend a fair chunk or our working lives advising on glazing specifications and optimizing this together with shading, glazing areas and location to provide the best possible scenario regarding daylighting, ventilation, overheating and heat loss.

Autodesk have a useful article on glazing properties which defines glazing Thermal conductance (U-value), g-value (Solar Heat Gain Coefficient) and Visible Light Transmittance (Tvis).

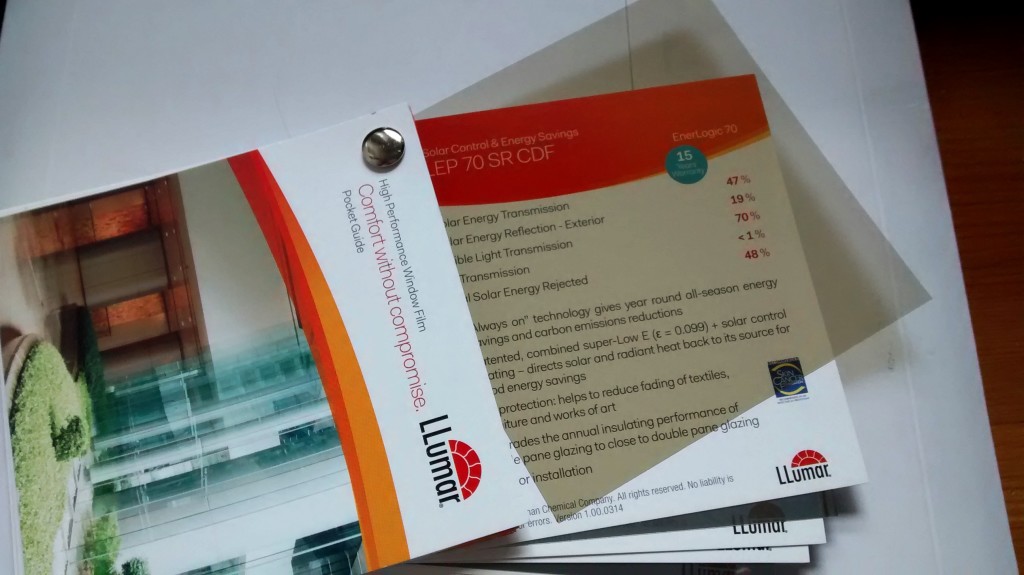

This article looks at how these properties can be modified by applying glazing films to tailor performance for a particular application. These films can be retrofitted internally or externally to existing or new glazing.

We will focus on two types of glazing film and look at the physics behind them:

– Solar control films

– Low emissivity films

Solar control window films reduce the g-value (transmitted solar heat) of the glazing and are used to reduce the solar heat gains into a space in order to prevent excessive cooling loads and/or overheating as well as to reduce glare. These films will usually have either a highly reflective or a tinted appearance depending on the individual film properties. The reduced g-value causes less solar radiation to be transmitted through the glazing, instead this is reflected or, to a lesser extent, absorbed by the glass and re-radiated to outside.

In the winter the addition of the film will reduce the useful solar heat gains and therefore will increase heating loads to the space. Therefore it is important to consider both the winter and summer energy balance when specifying window film. In addition solar control films will usually reduce the visible light being transmitted through the glazing into the room, therefore any necessary increase in lighting energy also needs to be considered as part of these calculations. However, this is not necessarily a straightforward calculation as the reduced glare from the window with applied film may actually lead to reduced use of window blinds and therefore increased daylight in the space.

Low-emissivity window films work in a different way, increasing the percentage of radiant heat which the glazing reflects internally back into the room thus reducing heat losses. This reduces heating loads and improves winter thermal comfort for occupants.

The effect of applying low-e films is more pronounced for single glazing, with a lesser effect when they are is applied to double glazing. Therefore they may be more appropriate for applications where retrofit of double glazing is not practical, such as historic buildings.

So how do they work?

First the Physics – what is emissivity? A definition from NPL (National Physical Laboratory):

All objects at temperatures above absolute zero emit thermal radiation. However, for any particular wavelength and temperature the amount of thermal radiation emitted depends on the emissivity of the object’s surface. Emissivity is defined as the ratio of the energy radiated from a material’s surface to that radiated from a blackbody (a perfect emitter) at the same temperature and wavelength and under the same viewing conditions. It is a dimensionless number between 0 (for a perfect reflector) and 1 (for a perfect emitter).

So for glazing surfaces, the lower the emissivity, the more radiant heat is reflected from the surface. The surface of non-coated glass without window film has an emissivity of around 0.84. Manufacturer’s data for low-e window films specifies surface emissivities as low as 0.04.

These films are installed on the inside surface of the glazing and reflect radiant heat from heating systems, warm surfaces and occupants back into the room. Thermal comfort is dependent on both the air temperature and the mean radiant temperature (MRT) of the space, with the MRT being dependent on the temperature and emissivity of the room surfaces. Increased MRT will lead to occupants feeling warmer for the same room air temperature and therefore a lower air temperature can be used to achieve the same comfort level, potentially saving energy.

As more heat is reflected by the glazing, rather than absorbed, the glazing temperature will be slightly lower than the same glazing without the film. This reduces both conduction heat loss through the glass and radiant heat transfer from the outside surface of the glazing, this effect reduces heat losses and can therefore provide another means to reduce room heating loads.

In addition, surface resistance is dependent on emissivity, with a low emissivity inner surface the glazing will have a higher inner surface resistance. This leads to a lower glazing U-value and therefore less heat transfer through the glazing. However this effect is usually ignored in U-value calculations, surface resistances used for calculations are generally those applicable to high emissivity surfaces as specified in BS EN ISO 6946.

Low-emissivity window film will also reduce the glazing g-value. Although this reduces the useful solar heat gains in winter, this is offset by the benefits described above. In summer the reduced g-value will lead to similar effects to a solar control film.

Modelling predictions

The data from Eastman states that the Enerlogic LEP35 low-e window film can reduce the U-value of single glazing from around 5.8 to 3.3 W/(m2·K) (these U-values are so-called ‘centre pane’ values for the glazing only, ignoring the performance of the frame and spacer). This is a significant reduction in U-value, greatly reducing heat losses through the glazing. However it should be noted that modern double or triple glazing can achieve a centre-pane U-value of around 1.2 W/(m2·K) or lower.

A simple 6 metre square office, with one fully glazed facade, was modelled in IES both with and without Eastman performance window film applied to the inside surface of the single glazing. The model was rotated to simulate various glazing orientations. The CIBSE TRY and DSY weather files were applied.

Results predict that the film is capable of reducing heating loads in winter due to the reduced U-value of the glazing with applied film. For a single cold day in February, room daily heating loads for the hours 8am to 7pm were reduced by around 50% for south facing glazing and by around 65% for north facing glazing. The average internal glazing temperature was reduced by around 28% for this period, leading to reduced heat loss .The variation in results by orientation highlights the fact that orientation is an important consideration when specifying window film.

The effect on thermal comfort was also assessed. It was expected that the greater percentage of incident radiant heat being reflected back into the room would improve winter thermal comfort conditions. Thermal comfort was represented by the average Predicted Mean Vote (PMV) metric. This was predicted (for the hours 8am to 7pm) to increase from approximately -0.29 to -0.06 for east facing glazing and from approximately -0.34 to -0.10 for North facing glazing. Although the differences are small, this represents a move from a slightly cool to a more neutral thermal environment and therefore an increase in thermal comfort.

The Enerlogic film modelled reduced the glazing g-value from 0.84 to 0.26 and therefore it was expected that a reduction in summer room cooling loads would be predicted due to the much reduced solar heat gains. For a hot summer day, peak cooling load was predicted to be reduced by 52% and for the hours 8am to 7pm, the total cooling load was predicted to be reduced by 48%.

In conclusion, window films can make a significant difference to glazing thermal performance and occupant comfort and it would seem sensible to consider window films during refurbishment if budget or other constraints don’t allow a full upgrade of glazing, or in order to cost effectively target a problem in an existing building, such as glare or excessive solar gain.

Posted by Claire Das Bhaumik

Posted by Claire Das Bhaumik- Posted in Research

May, 18, 2015

May, 18, 2015 Comments Off on Inkling carrying out modelling to assess window film performance

Comments Off on Inkling carrying out modelling to assess window film performance

Susie: 07972 263 676

Susie: 07972 263 676

Join Us On In.com

Join Us On In.com